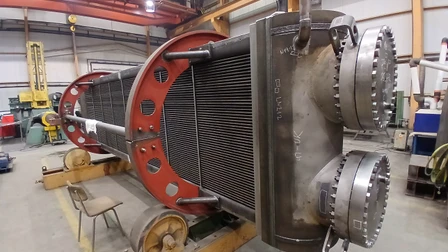

Tubular heat exchangers

We design and manufacture steam condensers, high-pressure and low-pressure heaters, oil and air coolers, and vaporisers. We will prepare a complete technical solution with thermal-hydraulic and strength calculations and detailed drawing documentation according to customer requirements. We manufacture in our own production plants and are able to design and supply exchangers with an operating pressure of up to 30 MPa (300 bar) and a medium temperature of 300°C.