Own production facilities

MICo's production base is located in two areas: Hrotovice and Kramolín, which are in the immediate vicinity of the Dukovany Nuclear Power Plant (6 and 8 km). The total production area is 60,000 m2.

Our two factories, with a total production area of 60,000 m 2, cover the entire production process and technological operations for very large and heavy products.

MICo's production base is located in two areas: Hrotovice and Kramolín, which are in the immediate vicinity of the Dukovany Nuclear Power Plant (6 and 8 km). The total production area is 60,000 m2.

We are technologically self-sufficient in production. We use subcontractors and cooperation partners based on customer requirements for volume or deadline-related production capacity.

The specifications of our production capabilities are outlined below.

Maximum diameter: approx. 5,500 mm

Maximum weight: approx. 150,000 kg

98% of the production area is served by cranes.

Installation pit: 5×12 m, depth 4.5 m

NC burning machine: maximum dimensions 3,240 x 6,000 mm

Burning: maximum thickness of CS steel 350 mm

Plasma: maximum thickness of SS steel 50 mm

Maximum length of the shaft: 3 050 mm

Maximum thickness: 65 mm

Maximum diameter: 5,500 mm

Minimum diameter: 380 mm

Maximum diameter: 4,200 mm

Maximum length: 2,500 mm

Maximum weight: 40 000 kg

Classic + NC

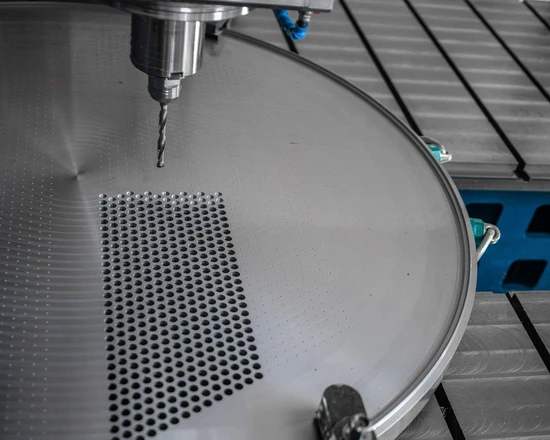

Maximum hole diameter: 45 mm

Maximum workpiece weight: 40 000 kg

Range of rolled tubes from 15 mm to 114.3 mm

Metody:MMA, MAG/MIG, TIG, SAW

Orbital welding of tube bundles without or with preheating.

CS/SS welding of tube sheets with weld overlay

Chamber annealing furnace 7500 x 2700 x 2600 mm, temperature up to 850 °C

Resistance equipment for annealing and preheating, max. power 96 kW, temperature up to 1200 °C

Performing standard surface treatments on carbon and stainless steels

X-ray testing, ultrasonic testing, penetrant testing, magnetic testing, hardness measurement.